27.12MHz

RF Technology and Advantages

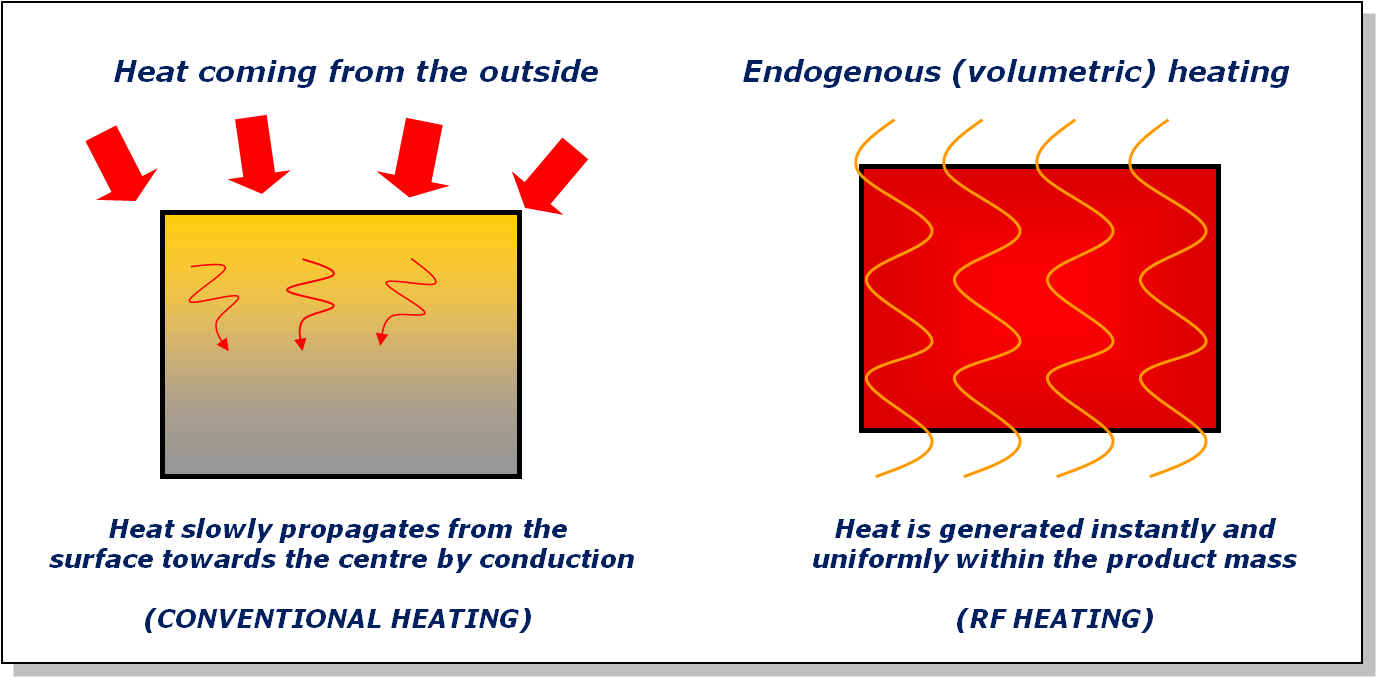

RF VS Conventional Heating

Conventional heating method:

Many times, the materials that need to be dried or heated are poor conductors of heat, whether through air, steam or liquid to conduct heat, if you want to improve efficiency, traditional heating methods are inseparable from two key factors: thermal energy (temperature) and mechanical energy (forced penetration). For example, the temperature is set very high, and the strong wind is used to make the heat reach the material center as quickly as possible. However, sometimes the materials that need to be dried or heated cannot accept higher temperatures, or the size of the material itself is very large, the density is very high, and even some materials can not accept any external force (strong wind), and the conventional heating method has encountered great challenges.

Disadvantages of conventional heating methods:

◆ Low energy efficiency. Not just heating water, but also heating the material and the environment, low energy utilization.

◆ Low efficiency. The efficiency of drying/heating depends on the temperature and the speed of heat transfer.

◆ Ununiform. The surface gets heated/dried first, and by the time the center reaches the heated/dried effect, the surface has already been over-heated/dried.

And other adverse effects due to high temperatures or strong winds.

Radio-frequency heating:

The main characteristics of the heating/drying process generated by the RF field are as follows:

◆ Endogenous heating. Heat energy is not introduced into the product by an external heat source through its surface, but is directly generated internally as a whole, simultaneously at all points containing water.

◆ Selective heating. Since the energy of the electromagnetic field is mainly absorbed by water rather than the product itself, only where there is water will heat up.

◆ Good heating permeability. The radio frequency field of 27.12MHz can directly penetrate products with a thickness of 0.5-1 meters, in other words, products with a thickness of less than 0.5 meters can be heated as a whole at the same time.

◆ Precise control. Since the absorption of electromagnetic energy is proportional to the water content of the product, the desired heating/drying effect can be achieved by controlling the RF power as well as the heating time.

Thanks to these characteristics of RF heating, there are many advantages to heating/drying through RF than conventional heating methods, the most important of which are as follows:

◆ High energy efficiency. (Electromagnetic energy instantly acts directly on the entire wet product, without energy loss to the external environment, all the energy goes into the heating/drying process)

◆ Fast heating speed. (Regardless of product shape, size, density, etc.)

◆ Excellent heating/drying quality. (All the problems caused by heat transfer disappear, so the product can be heated/dried quickly and uniformly to achieve the desired result)

◆ Improve working conditions. (low noise, no heat scattering, no smoke)

◆ Continuous production, automation system can be equipped easily. (PLC control system)

No. 98, Lane 4788, Bao 'an Highway, Anting Town, Jiading District, Shanghai

Copyright of the page: Shanghai Deyi Machinery Manufacturing Co., Ltd www.300.cn SEO Privacy Policy